Adhesives are substances that hold materials together by a chemical attachment that resists separation between surfaces. They function by forming strong chemical bonds between surfaces and then hardening, or curing, to solidify the bond. Stronger adhesives have a liquid that seeps into the surfaces to form a bond that is further strengthened by the body of each surface. Adhesives can be in different forms, such as liquid glue, foam tapes, or epoxy mold. Learn more about what are adhesives and how do adhesives work through this blog.

What is the oldest adhesive?

Nature, among many oldest things, probably also houses the oldest adhesive. It may be difficult to pinpoint the first occurrence of adhesives in nature, but we can determine a few candidates for the oldest adhesives.

A natural mucus secreted by gastropod mollusks called snails would be a promising candidate for the oldest adhesive. Snails produce ‘snail slime’ to protect themselves from scrapes and cuts as they slither around the world. Not only does snail slime have beauty benefits, but it is also the ultimate adhesive model as it can be switched on and off as needed. Snails can stick and unstick themselves to surfaces on steep inclines, vertical windows, and even upside down! Learn more about this alleged ‘oldest adhesive’ on Quora.

A natural mucus secreted by gastropod mollusks called snails would be a promising candidate for the oldest adhesive. Snails produce ‘snail slime’ to protect themselves from scrapes and cuts as they slither around the world. Not only does snail slime have beauty benefits, but it is also the ultimate adhesive model as it can be switched on and off as needed. Snails can stick and unstick themselves to surfaces on steep inclines, vertical windows, and even upside down! Learn more about this alleged ‘oldest adhesive’ on Quora.

The bark of a birch tree provides yet another example of adhesives in nature. Neanderthals used this oldest known glue to affix a sharpened piece of flint to a wooden shaft when crafting spears. While there are various possible methods that Neanderthals used to extract tar from birch bark, the ancient hunters realized the adhesive properties of tar and creatively utilized it with possibly the first industrial process – extracting glue. To further understand the history, you can study how neanderthals made glue.

How were the first adhesives and adhesive tapes formulated?

The modern adhesive applications began with bees. When woodworkers of ancient Egypt needed to hold materials together, they used the sticky properties of beeswax and resin to create glue. In 1925, the invention of adhesive tapes capitalized on reducing the drawbacks of using epoxy adhesives. Richard Drew, the inventor of adhesive tapes, had no experience in adhesives but he had a strong frustration with the ‘masking off’ color application procedure used in auto shops. His frustration evolved into a passion that motivated Drew to introduce masking tape – an adhesive that can be removed from dry paint without peeling it off. Learn more about the history of modern adhesive tapes and how they evolved into household items.

Why do adhesives bond to a surface and not stick to themselves?

Imagine you have a little fresh glue stuck to your hands from an arts and craft project. To get that glue off, you quickly rub your hands, creating heat from friction and causing molecules of the adhesive to stick to each other rather than to your hand, creating a small, sticky, semi-solid spherical ball of glue. You increase the surface tension by rubbing your hands, which causes molecules in the adhesive to bond with each other.

The intermolecular forces of a liquid are indeed responsible for adhesion. Resolved by differences in surface energy and surface tension, there is a war between these molecules sticking to each other and forming a sphere versus binding a solid surface and spreading along its body. The lower surface tension of the liquid and higher surface energy in the surface results in the adhesive liquid spreading across the body of the surface, which leads to greater contact between the adhesive and the surface, causing higher adhesion. The Spreading Coefficient defines this ratio between the surface tension of an adhesive liquid and the surface energy of a surface. Learn more about the forces involved in adhesion by reading about surface tension and adhesion.

What are adhesive tapes?

Adhesive tapes are combinations of an adhesive film and a backing/carrier material. There are several advantages to using adhesive tapes over fasteners, welding, screws, or liquid adhesives to bond surfaces. You can find more information about the basics of adhesive tapes on our blogs and website.

Adhesive tapes are combinations of an adhesive film and a backing/carrier material. There are several advantages to using adhesive tapes over fasteners, welding, screws, or liquid adhesives to bond surfaces. You can find more information about the basics of adhesive tapes on our blogs and website.

What are the different types of adhesive tapes?

There are various types of adhesive tapes, each focused on different applications. The application of heat-activated tapes, for instance, requires a heat source of usually 180°F or higher. Similarly, a water-activated tape becomes sticky when moistened. Another common type of adhesive tape is Pressure Sensitive Tapes (PSA). A ‘bonding pressure’ (15-30psi), applied by a finger or a hand, is sufficient to attach PSAs on a surface at room temperature and in dry form.

What are the different types of adhesives and carriers in adhesive tapes?

A list of adhesive materials commonly found on tapes includes Epoxy, Rubber, Acrylic, Silicone, and Polyurethane. Each of these materials has specialized applications. Silicone, for example, is flexible and resistant to very high temperatures, but its synthetic properties make it ideal for medical purposes. Conversely, polyurethane adhesives are more durable and provide resistance against impact. Moreover, adhesive tapes involve the use of various carriers like paper, foam, and polyester. Their level of strength or the environment of the tape is a differentiating factor for adhesive tapes. You could study more information about adhesive and backer on tapes.

What industries use adhesives?

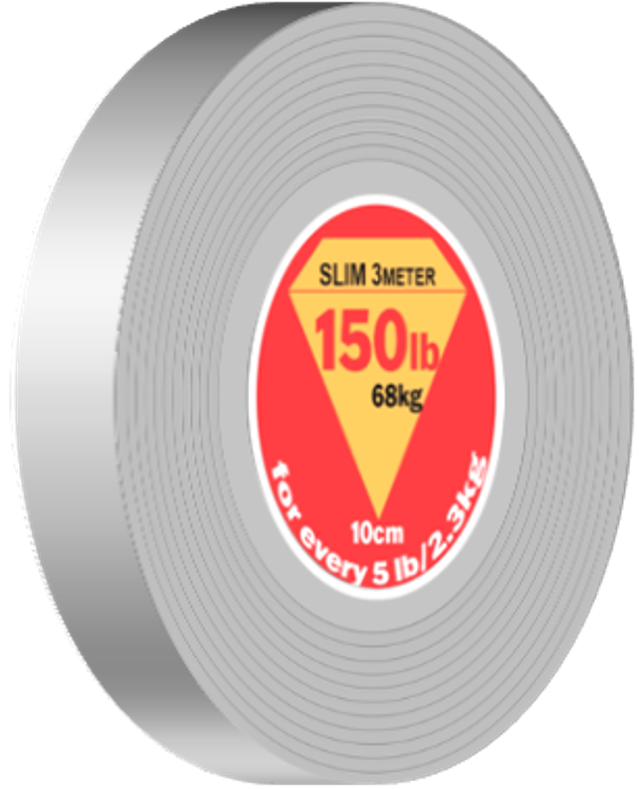

From rockets and airplanes to frozen pizza, a wide range of industries uses adhesives. Simple processes such as impermeable plastic packaging or paper glued on items for marketing could use heat-activated tapes. Windows of airplanes and KLAPiT steel tapes use high-strength pressure-sensitive tapes for durability and reliability. Not only are adhesives used in a variety of industries, but they are also used for a range of applications.

What are pressure-sensitive adhesives? How do pressure-sensitive adhesives work?

Pressure-sensitive adhesives (PSA) are an integral part of the adhesive tape market with many industrial and commercial functions. They are used for packaging, mounting, masking, and electrical devices among other applications. A ‘bonding pressure’ (15-30psi) applied by a finger or a hand is sufficient for PSAs to release from their rubber-, polyacrylate-, and silicone-based adhesive from a carrier of paper and/or foam. Upon application of pressure, PSAs release the stored liquid glue from their body which causes the tape carrier to become a part of the surface after curing.

How does the structural design of an adhesive contribute to bonding?

Various aspects contribute to the successful bonding of an adhesive to a surface. While material and surroundings may have an impact on strength and durability, the structural design of the adhesive is primary to successful bonds. Two requirements to the structural design of adhesives must be met for creating a bond with good, long-term stability: a large contact area between adhesive and surface, and the prevention of loads that develop stress peaks in the bond.

What factors contribute to a strong adhesive bond?

The physics of a strong adhesive bond can be simplified into three phenomena.

Firstly, we account for phase changes – a physical and chemical process that all adhesives undergo. Adhesives become stronger as they cure from liquid to solid; therefore, they have strong interactions with the surface after curing without stress.

Secondly, the intermolecular interactions – including chemical bonds, physical interactions, and micro-mechanical adhesion – contribute to a strong adhesive bond. The chemistry of these interactions defines the relevance of the material of an adhesive and a surface to the strength of their bond.

Thirdly, we consider the wetting of the substrate surface by the liquid adhesive. Wetting is a prerequisite for adhesive. While wetting alone does not account for good, long-term adhesion, it is a major contributing factor as it is determined by the surface tension of the adhesive and substrate. You could study more about adhesive bonds to further understand each of these phenomena.

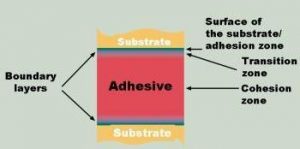

How can I visualize the bonding between two surfaces by an adhesive?

Adhesive and substrate bonds can be visualized in different zones. The adhesion zone would be on the surface of a substrate (where the surface and adhesive come into contact), and the two adhesion zones on either side of the adhesive would form the boundary layers. The transition zone would be on the adhesive in the vicinity of the surface. The cohesion zone would be in the center of the adhesive, connecting the transition zones on either side of the adhesive.

The adhesive would be in its normal state in the cohesion zone, with strong intermolecular forces between adhesive molecules. The adhesive would have a modified structure and composition in the adhesion zone based on its interaction with the substrate. The transition zone is where this structure and composition are continuously changing during curing. For instance, the diffusion of adhesive molecules into the pores of the surface would occur along this zone. This cross-section of adhesive bonds helps us better understand the science of adhesion.

Can surface treatment affect adhesion?

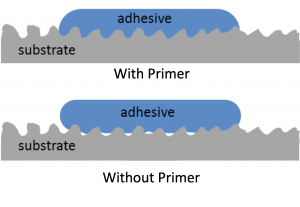

Conditions of the substrate and surroundings greatly impact the strength of adhesion. For better adhesion, we need good wetting properties on the substrate surface.

Conditions of the substrate and surroundings greatly impact the strength of adhesion. For better adhesion, we need good wetting properties on the substrate surface.

This involves an even spread of the adhesive onto the substrate. The surface must also have good bonding properties as it cooperatively bonds with adhesives. Complimentary bonding properties of surfaces and adhesives would allow for strong chemical bonds and useful intermolecular interactions during curing.

Moreover, the surface layer must be strongly attached to the substrate – the surface should not peel off the substrate and the adhesive must seep into the substrate through the surface. Also, the substrate must not change after adhesion. If the substrate corrodes after adhesion, for example, the chemical process of oxidation may weaken the adhesive bond.

Therefore, we can understand the benefits of surface treatment for adhesive. Using the right surface along application of a primer would manage all the requirements to marginally improve adhesion.

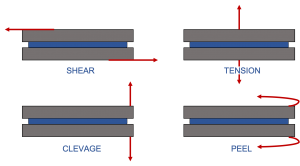

How can an adhesive come off?

Various stress forces may contribute to weakening the adhesive. Sheer, tension, cleavage, and peel stresses impact the adhesive bond and may break the bond over time. Sheer forces include dragging surfaces attached by an adhesive in opposite directions – like gravity pulling mounted painting. Tension requires applying force proportional to the surface, pulling it from the adhesive. Cleavage, like tension, involves pulling the surface from the adhesive, but from the top or bottom of the surface. Peel means pulling the surface backward off from the adhesive. While sheer and tension are more impactful, all stress forces are important to consider when using adhesives. To know more about how adhesive comes off, you could read more about each of these stress forces.

Various stress forces may contribute to weakening the adhesive. Sheer, tension, cleavage, and peel stresses impact the adhesive bond and may break the bond over time. Sheer forces include dragging surfaces attached by an adhesive in opposite directions – like gravity pulling mounted painting. Tension requires applying force proportional to the surface, pulling it from the adhesive. Cleavage, like tension, involves pulling the surface from the adhesive, but from the top or bottom of the surface. Peel means pulling the surface backward off from the adhesive. While sheer and tension are more impactful, all stress forces are important to consider when using adhesives. To know more about how adhesive comes off, you could read more about each of these stress forces.